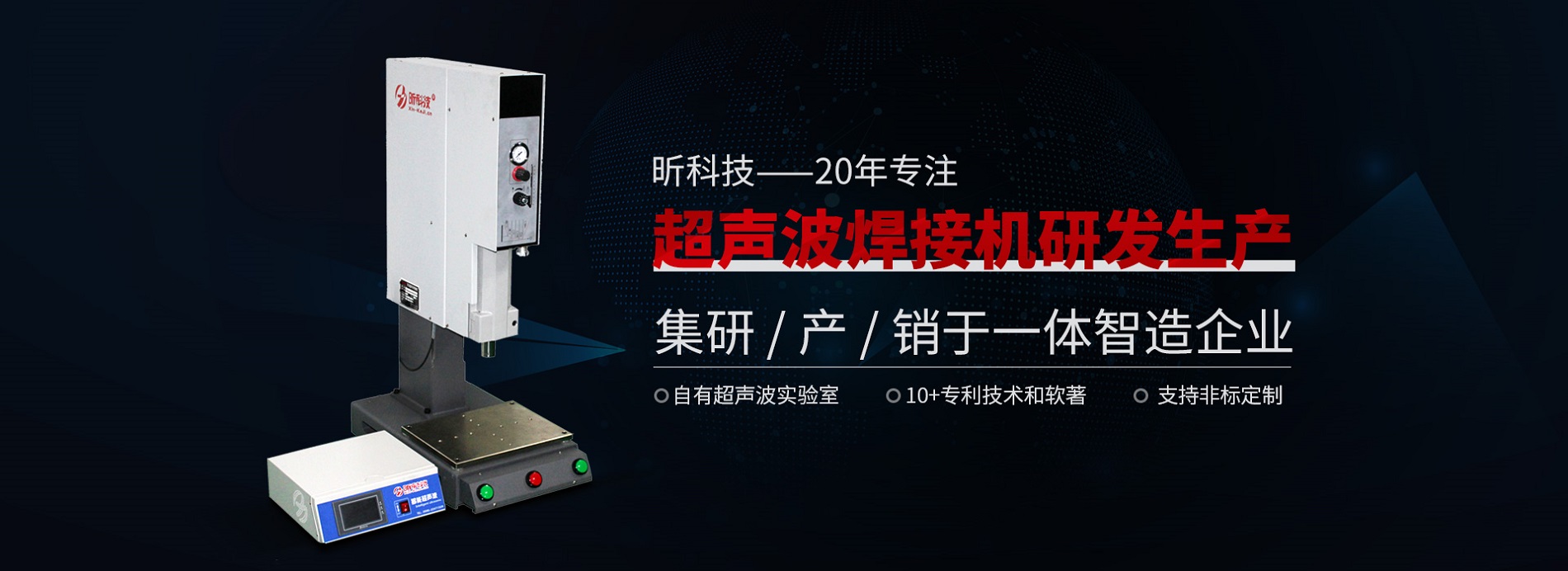

智能超声波焊接机CX-2020ZN

超声功率 Ultrasonic power 1000W 1500W 2000W 2600W

焊接时间 Weld time 0.001-9.999

保压时间 Hold pressure time 0.001-9.999

工作行程 Work distance 75mm

工作气压 Work pressure 0.15-0.8Mpa

工作电源 Voltage AC220V,50Hz

尺寸 Size of Shape 400×600×1400mm 400×600×1400mm 500×600×1400mm 600×700×2000mm

净重 Net weigh 120KG 130KG 145KG 180KG

产产品特点:

◆智能频率跟踪

◆功率无极调节

◆超大液晶显示屏

◆IGBT功率模块输出

◆功率强劲稳定

◆时间控制模式

Product?features:?

◆Intelligent?frequency?tracking?

◆The?infinite?power?to?adjust??

◆Large?LCD?screen?

◆IGBT?power?module?output?

◆Strong?and?stable?power?

◆Time?control?mode?(optional)

1、智能触摸控制系统,超大液晶屏显示,极致简单的操作,有效提高生产效率。

2、真正数字化自动追频电路,频率全自动搜索补偿,每时每刻保持最佳谐振状态,使生产过程精准、稳定。

3、无级振幅控制,以5%递增,大小胶件均能完美焊接 ,有效减少激穿,烫伤等不良品。

4、内设模具电流过高保护,频率偏移保护,总输出过大保护等多种模式,安全无虞,持久耐用。

5、宽频带设计,适应各种大小焊模和不同的设计模具。

6、采用FET场效管做功率放大,比传统硅功率管反应速度快100倍以上,输出更稳定有力。

7、机器故障自动检测,方便维修。

8、时间、能量、深度控制模式可选,生产无忧,品质保证。

1, the intelligent touch control system, large LCD screen display, the extreme simple operation, effectively improve the production efficiency.

2, real digital automatic tracing frequency circuit, frequency automatic compensation, at all times to maintain optimum resonance condition, make the production process of precision, stability.

3, stepless amplitude control, increased by 5%, the size of plastic parts can perfect welding, effectively reduce the shock wears, scald and other defective products.

4, internal mold high frequency offset current protection, protection, total output of a variety of modes of large protection, safe, durable.

5, the broadband design, adapt to various sizes of welding mould and mould design of different.

6, using the FET field effect tube power amplification, the reaction rate is more than 100 times faster than traditional silicon power transistor, the output is more stable and powerful.

The main parameters:

Automatic detection of

7, machine failure, convenient repair.

8, time control mode optional, worry about production, quality assurance.

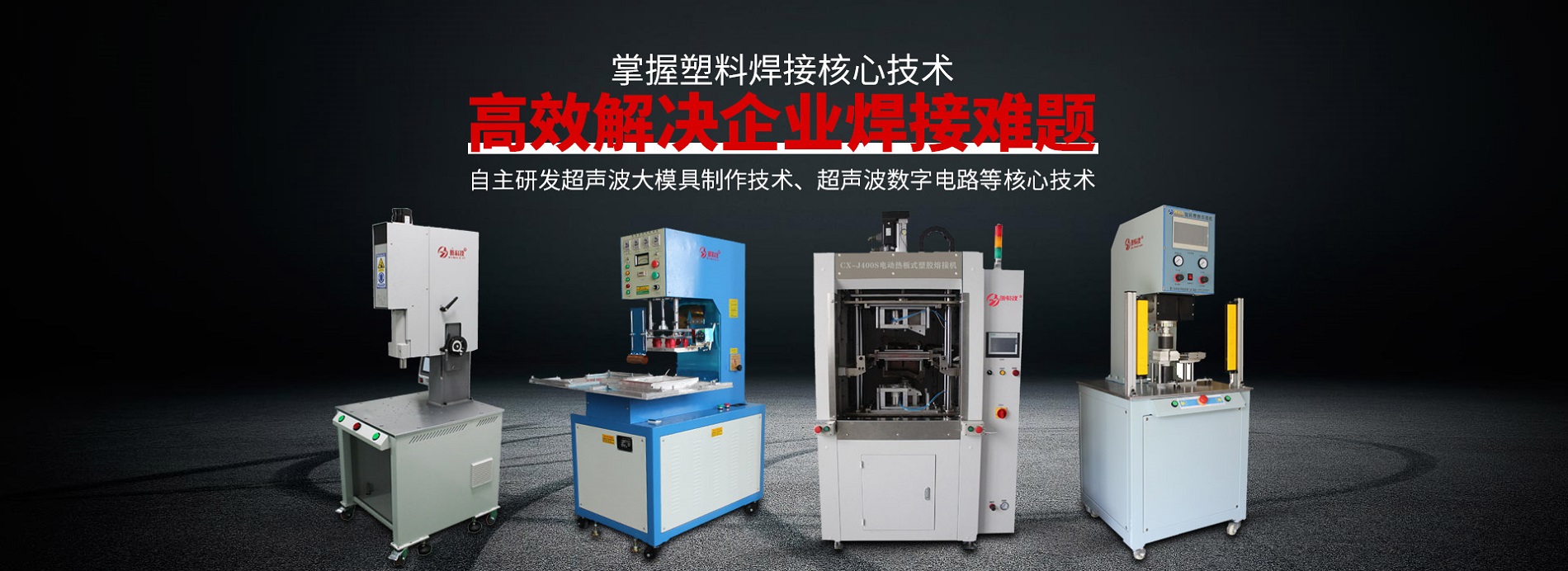

Z系列时间控制:

全智能时间控制系统,电脑控制、开机自检、自动追频、智能保护,精准时间控制0.001秒,便捷更耐用。

焊接时间 Weld time 0.001-9.999

保压时间 Hold pressure time 0.001-9.999

工作行程 Work distance 75mm

工作气压 Work pressure 0.15-0.8Mpa

工作电源 Voltage AC220V,50Hz

尺寸 Size of Shape 400×600×1400mm 400×600×1400mm 500×600×1400mm 600×700×2000mm

净重 Net weigh 120KG 130KG 145KG 180KG

产产品特点:

◆智能频率跟踪

◆功率无极调节

◆超大液晶显示屏

◆IGBT功率模块输出

◆功率强劲稳定

◆时间控制模式

Product?features:?

◆Intelligent?frequency?tracking?

◆The?infinite?power?to?adjust??

◆Large?LCD?screen?

◆IGBT?power?module?output?

◆Strong?and?stable?power?

◆Time?control?mode?(optional)

1、智能触摸控制系统,超大液晶屏显示,极致简单的操作,有效提高生产效率。

2、真正数字化自动追频电路,频率全自动搜索补偿,每时每刻保持最佳谐振状态,使生产过程精准、稳定。

3、无级振幅控制,以5%递增,大小胶件均能完美焊接 ,有效减少激穿,烫伤等不良品。

4、内设模具电流过高保护,频率偏移保护,总输出过大保护等多种模式,安全无虞,持久耐用。

5、宽频带设计,适应各种大小焊模和不同的设计模具。

6、采用FET场效管做功率放大,比传统硅功率管反应速度快100倍以上,输出更稳定有力。

7、机器故障自动检测,方便维修。

8、时间、能量、深度控制模式可选,生产无忧,品质保证。

1, the intelligent touch control system, large LCD screen display, the extreme simple operation, effectively improve the production efficiency.

2, real digital automatic tracing frequency circuit, frequency automatic compensation, at all times to maintain optimum resonance condition, make the production process of precision, stability.

3, stepless amplitude control, increased by 5%, the size of plastic parts can perfect welding, effectively reduce the shock wears, scald and other defective products.

4, internal mold high frequency offset current protection, protection, total output of a variety of modes of large protection, safe, durable.

5, the broadband design, adapt to various sizes of welding mould and mould design of different.

6, using the FET field effect tube power amplification, the reaction rate is more than 100 times faster than traditional silicon power transistor, the output is more stable and powerful.

The main parameters:

Automatic detection of

7, machine failure, convenient repair.

8, time control mode optional, worry about production, quality assurance.

Z系列时间控制:

全智能时间控制系统,电脑控制、开机自检、自动追频、智能保护,精准时间控制0.001秒,便捷更耐用。

上一条:20K高精度智能超声波焊接机

下一条:一体式超声波焊接机(能量)